Innovation in CPG is often associated with new flavors, formats, or packaging. The stuff we can see and hold and taste. It’s fun and exciting.

But behind the scenes, often quietly, AI is transforming something far less visible—and far more impactful: how companies predict and respond to demand.

Welcome to the era of intelligent forecasting, and if you’ve ever run any kind of CPG company you know that this is a very big deal indeed.

Why it matters now

Traditional demand planning has always relied on lagging indicators: past sales, historic seasonality, and spreadsheets – often built on gut feel. But that model breaks down in a world of climate volatility, fluctuating consumer behavior, and global supply chain fragility coupled with political uncertainty.

Enter AI.

What we’re witnessing is a systemic upgrade

- Walmart’s “Eden” platform cut food waste by $86 million in one year through smarter fresh-product forecasts.

- Danone, Zara, and Accenture deployments improved forecast accuracy by 6–8 points, unlocking $100–130 million in efficiency benefits.

- One implementation dropped MAPE forecast error from 35 percent to 15 percent, saving over $200K per month in working capital.

- Kraft Heinz improved forecast accuracy by 8 percent, cut excess inventory by 25 percent, and reduced food waste by 10 percent. (Yes, I know, they are still going through troubled times, but that’s managerial incompetence whilst bleeding the company dry – I wrote about the idiocy causing this a few weeks ago).

- back to positive things, Unilever’s ice cream division boosted Swedish forecast accuracy by 10 percent and U.S. sales by 12 percent by integrating weather-based AI forecasting.

1. Predictive clarity over reactive guessing

Machine learning models are reshaping demand forecasts. By layering internal sales data with external signals—from weather to social chatter—AI generates highly adaptive predictions that outperform static planning cycles. A cold summer means fewer strawberry sales during Wimbledon. A drought in Vietnam affects the demand for coffee in Amsterdam.

2. Real-time recalibration

Set it and forget is is not a viable method anymore. AI-powered tools continuously monitor variables and adjust forecasts in real time. Whether it’s a viral TikTok trend or a port delay in Asia, these systems adapt quickly to reduce surprises.

3. Inventory that moves like a portfolio

Smart forecasting means smarter inventory. AI balances stock levels across channels and locations to prevent both overages and stockouts. This reduces carrying costs and food waste—two persistent CPG pain points.

4. Demand sensing at the edge

Modern systems pull data not just from POS or ERP platforms, but from social trends, search data, and weather feeds. This helps detect hyper-local shifts in demand before they hit the shelf.

5. A more connected supply chain

AI enables better collaboration among retailers, manufacturers, and distributors. As of 2024, 65 percent of CPG companies are using AI in some capacity—61 percent specifically for supply chain optimization. Forecasts and inventory data can be shared more transparently, reducing mismatched expectations and lost sales.

What brands should be asking now

- Where are we still relying on human guesswork?

- What demand signals are we underutilizing?

- How can we use AI not just to predict demand—but to rewire how we meet it?

Strategic takeaways for CPG leaders

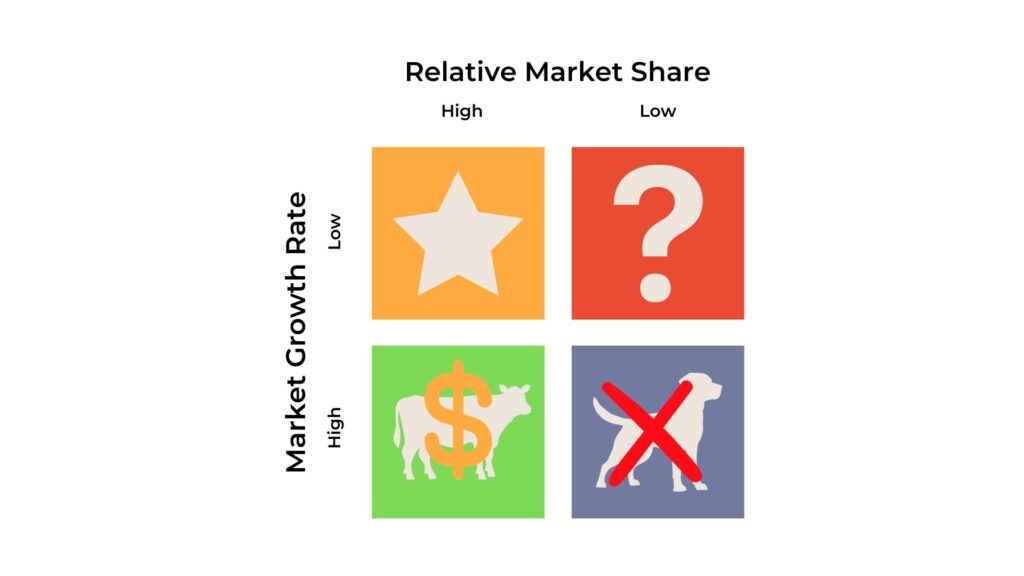

- Stop treating forecasting like a back-office function: It’s now a brand advantage.

- Make demand planning cross-functional: Let insights shape marketing, not just manufacturing.

- Invest in systems that learn: Static planning models can’t compete with adaptive AI.